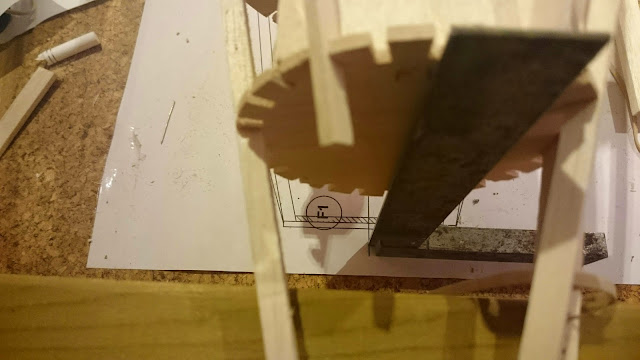

To keep the shape of the fuz I'm going to string the bottom before sheeting. So I've passed timber through the fuz to hold it level. Also making sure that it's ture to the plan.

Saturday 29 November 2014

Friday 28 November 2014

Test the retracts

I have just put the retracts in to test the fit. Electric retracts have been chosen for this model. The legs are the wrong size but I'll sort that out later.

Thursday 27 November 2014

Start to install the stringers

With the crutch pinned to the cradle. I checked the alignment (again) and started to install the stringers. This should fix the fuz shape.

Wednesday 26 November 2014

Dry fit the wing.

Every thing looks OK

The cnc cut formers seem to line up ok. The next thing to do dry fit the wing and check the wing angles.

Dry fit the formers

First CNC formers cut

CAD done

How it all started

I wanted to build a Jet! So having previously built a Ziroli Bearcat , I decided to go with a Ziroli Panther F9F.

The reviews I found on the Web were encouraging, it seems that the Ziroli Panther was originally designed for a ducted fan circa. approx 11Ib of trust. So a turbine of 14- 18 lb should be fine. Most builders of this model seem to use a P80 or something similar. Here in the UK we have Wren so a Wren 75 or Wren 80 should suffice.

When I mentioned to my mates that a new project was on the way and that I would be getting the plans converted to CAD, with the intention of having the parts cut on a CNC, four of them decided to build the same model.

So the process of converting the plans to CAD started.